A smaller building may have a single, computerised HVAC controller that operates the direct digital control (DDC) system. However, a large building normally requires a more complex system of controllers, divided into separate sections called ‘tiers’. Every manufacturer of an HVAC digital control system uses the DDC to perform pretty much the same functions. The catch is that each DDC system has different ways of letting you use these functions depending on the computer program being used.

In a Direct Digital Control (DDC) system, a controller is a dedicated computer, which can perform complex calculations and store a vast amount of input and output data, analyse trends, and automatically change set points for many systems and conditions.

A CCS technician communicates with controllers in the system via an operator-machine interface (OMI) such as a desktop, handheld terminal, or keypad which communicates with the controllers wired to manage major equipment such as a VAV terminals, chillers, cooling towers, or boilers. Service Technicians use the OMI for actions such as checking the status of each component and the status of the system, seeing trends that indicate potential system problems, displaying or printing out operating data for any component of a system, and changing settings.

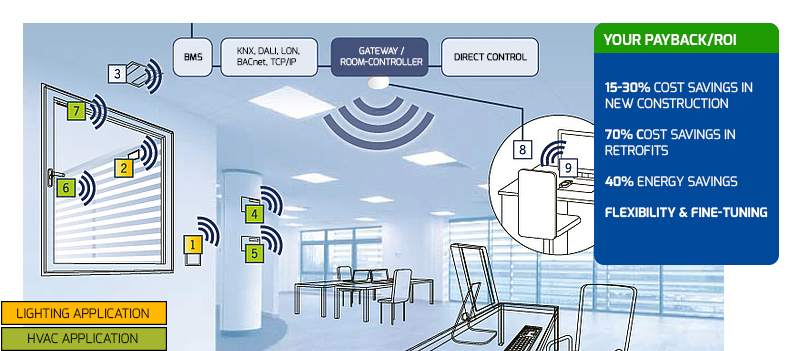

A DDC system that controls HVAC may also control many other building systems, so a technician can manage all building functions from one workstation.

‘Economising’ and ‘limiting’ settings are usually available for use, and most modern systems can be programmed with automated ‘responsive’ settings for the changing external environment, increasing plant efficiency.

DDC systems have become so advanced, they can be used to control even the most obscure building and occupancy schedules, cater to demand charge/load times, and save hundreds of operating hours every year.